Fibremax setting

the standard

For relevant testing

Rethinking Mooring for

Floating Wind

Early floating wind demonstration projects have exposed a critical challenge: traditional braided polyester ropes fail to deliver consistent, reliable performance as standalone mooring lines. While polyester offers inherent material benefits, these braided constructions exhibit a dramatic stiffness increase under tension—precisely when the floating platform requires compliance to safely absorb dynamic loads.

This excessive stiffness not only undermines mooring integrity but also has direct consequences for turbine performance, leading to:

· Elevated platform accelerations

· Increased structural fatigue

· Reduced system lifetime reliability

Tension Leg Platform (TLP) technology presents a unique challenge in mooring design: it requires high dynamic stiffness to ensure platform stability and performance under constant tension and extreme dynamic loads.

Recognizing the lack of suitable solutions in the market, FibreMax has taken decisive action—investing significantly in state-of-the-art testing equipment and methodologies to address the specific demands of the floating wind industry via FibreTech, the knowledge center

BEHIND THE MOORING REVOLUTION

FIBRETECH THE KNOWLEDGE CENTER

In the absence of industry standards for dynamic mooring testing, FibreMax chose not to wait. Instead, we took the initiative—investing heavily in state-of-the-art testing equipment and developing a custom, fit-for-purpose test program specifically designed to address the demands of floating offshore wind and other dynamic marine applications.

This program operates under FibreTech—our dedicated knowledge and innovation center, where data, testing, and engineering come together to shape the future of mooring.

Key Capabilities of FibreTech:

- 2 decades of innovation and in-depth fibre knowledge

- Fatigue testing under real-world dynamic conditions

- Compatibility with any fiber—including polyester, HMPE, aramid

- Validation of stiffness, creep, and load response over long life cycles

- Export of test-derived data to the proprietary Line Configurator

Proven Performance

with the FibreMax Line Configurator

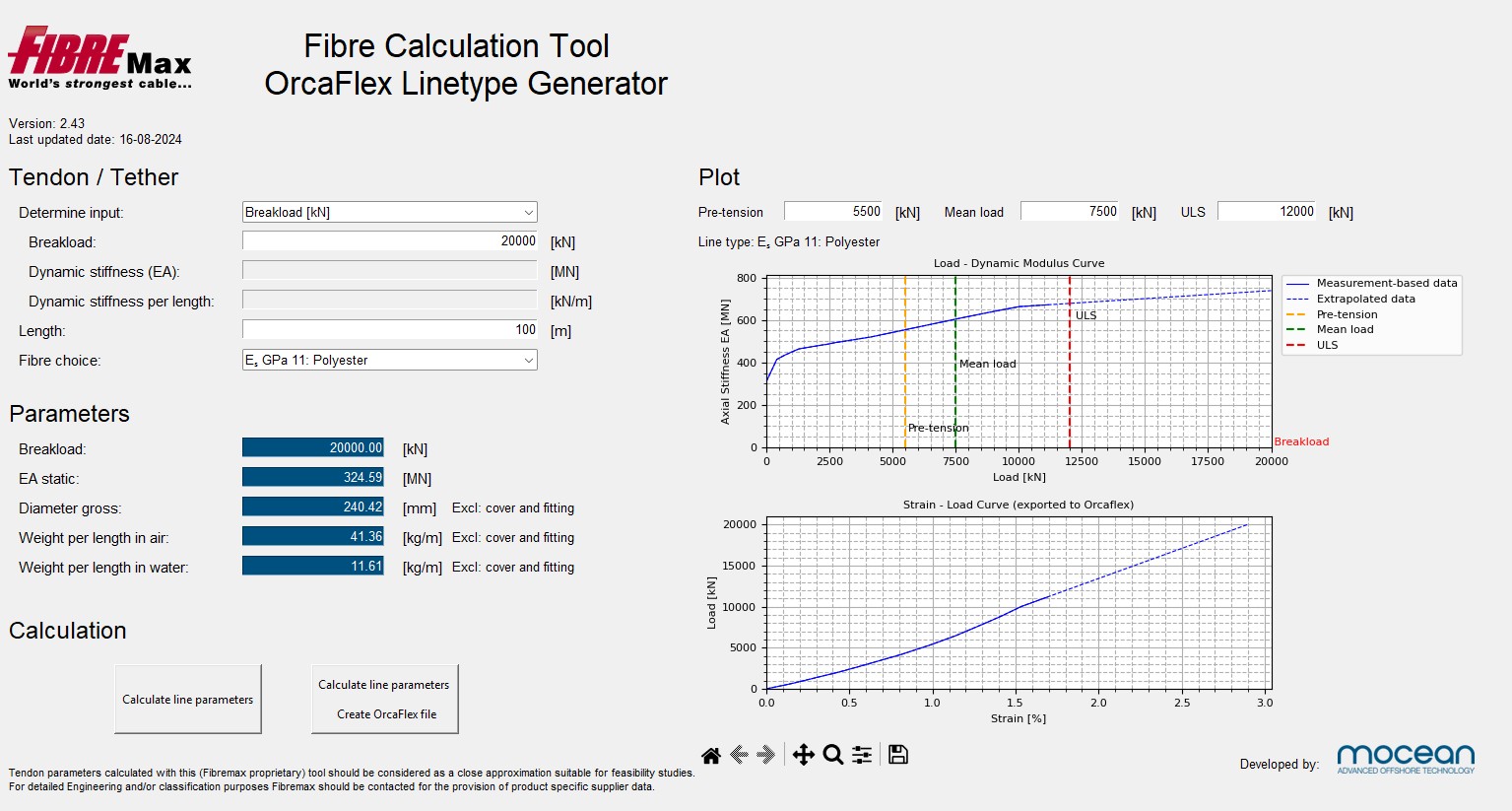

FibreMax takes the guesswork out of mooring system design with its proprietary Line Configurator—a powerful proprietary tool that enables demonstrable dynamic behavior modeling based on real, tested data.

With the Line Configurator, engineers and designers can:

- Visualize and fine-tune mooring line performance in real time

- Access exact dynamic stiffness curves tailored to their specific configuration

- Eliminate generic assumptions and oversimplified stiffness profiles

For seamless integration into project simulations, the configurator offers a one-click export to OrcaFlex DLL file —ensuring your OrcaFlex modeling environment reflects reality with precision.

No more assumptions. No more approximations. Just exact data for exact modeling.

Fibremax

Case study

Unmatched Aramid Mooring Capability

FibreMax is the only company in the world capable of manufacturing and demonstrating an aramid-based mooring tendon that:

- Is suitable for dynamic loading in offshore environments

- Has undergone extensive fatigue testing

(> 74 Million Dynamic Load cycle test at relevant parameters!)

- Has been proven to perform for over 30 years of service life

Thanks to the synergy between FibreTech’s advanced testing and FibreMax’s precision manufacturing, we’ve delivered what no one else can: an aramid tendon that combines high stiffness, low weight, and unrivaled fatigue resistance — DNV A.O.M. certified and ready for real-world deployment.