FIBREMAX INNOVATION

IN POLYESTER MOORING

Rethinking Polyester Mooring for Floating Wind:

Introducing PolyMax

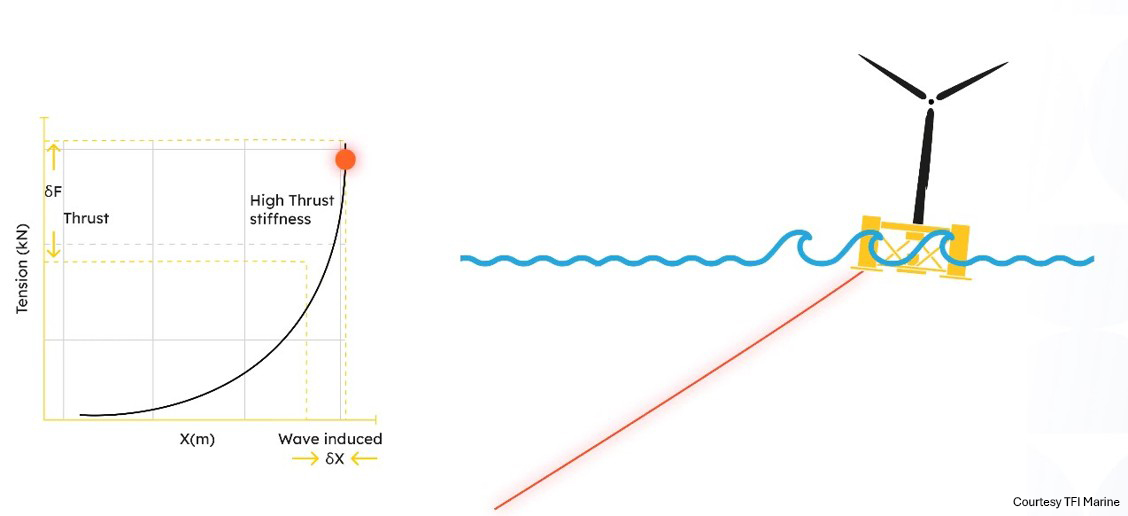

Early floating wind demonstration projects have exposed a critical challenge: traditional braided polyester ropes fail to deliver consistent, reliable performance as standalone mooring lines. While polyester offers inherent material benefits, these braided constructions exhibit a dramatic stiffness increase under tension—precisely when the floating platform requires compliance to safely absorb dynamic loads. This excessive stiffness not only undermines mooring integrity but also has direct consequences for turbine performance, leading to:

· Elevated platform accelerations

· Increased structural fatigue

· Reduced system lifetime reliability

Recognizing this gap, FibreMax has taken decisive action. Backed by rigorous testing, qualification, and development, we’ve engineered a fit-for-purpose polyester mooring solution designed to meet the specific demands of floating wind: PolyMax.

POLYMAX

FIT FOR PURPOSE

Oil & Gas heritage

Wind industry statistics indicate an estimated more than 150 different floater designs in various development and implementation stages, of which around 50 floating turbines were operational outside China in late 2024. These around fifty installations represent only a selection and can be subdivided in semi-submersible multi-point respectively single-point floater-mooring designs, spar-type, barge-type and tension-leg platforms (TLPs). Each topology and variant requires a unique dedicated mooring solution.

Many current floater designs and matching ‘traditional’ mooring-line designs originate from and build at Oil & Gas industry experiences. Manufacturers of these traditional mooring lines produce their multi-strand ropes from twisted fibres in a braiding process either in steel or a limited synthetic fibre choice, with Polyester, HMPE, and Nylon most common.

Shared feature of these decennia-old braided rope designs is strength and not stiffness being the primary parameter and design driver. Stiffness driven (EA) is a line’s resistance to stretching under load, while strength-driven ropes come with the abbreviation MBL meaning minimal breaking tensile load in kN.

High dynamic

stiffness

Key inherent characteristic of such’ strong-stiff’ braided multi-strand ropes is their unpredictable dynamic stiffness, which value is variable due to internal tension of synthetic fibres due to the twisting and braided construction, additionally there is internal compression and fibre-to-fibre abrasion which limits the choice of fibres. Another variable is the inaccurate lengths, and during operations the bedding in effect.

Overall bottleneck of these traditional rope designs is that there are too many variables, which results in up to 30% design inaccuracy range that in turn poses a substantial risk factor to such ropes application! Consequently, these traditional O&G configurations will need a tensioning device to compensate for the inaccuracy in mooring line length. The tensioner can either be located inline in the mooring line, or as an integrated part of the mooring brackets. In any case, it represent a considerable cost to the mooring system.

The suitable solution for this critical and thus ‘ultimate tendon’ application within FOW solutions is TLP, where traditional braided ropes in Polyester or steel wire ropes, designed for strength (MBL) cannot do the job without mooring tensioners . FibreMax’ offers here a well-scalable alternative solution with tendons made either in high-strength HMPE (like Dyneema DM20) or ARAMID (like Teijin Twaron) synthetic fibres and in exact (2mm per 300m) length control that is crucial for TLP application. Additional benefits include the skipping of post-tensioners, lightweight and compared to steel ropes no corrosion and/ or fatigue issues. Commitments from leading TLP-Pioneers are in already place.

‘Fit for purpose’

FibreMax is not disputing the quality of traditional braided ropes, however, this same specific ‘strong-stiff’ dynamic stiffness behaviour makes traditional Polyester ropes ‘not fit for purpose’ with semi-submersible and barge and spar-type floaters without clump weights and/or buoyancy elements as Integrated pats in the mooring line and the needed load-reduction-devises (LRD’s).

Main contributing reason is that these installations move continuously at six degrees of freedom near the water surface, which especially in adverse weather conditions causes wind and wave-induced shock loads. Experiences with some FOW-demonstration projects indicate that these negative impacts might cause at least part of costly premature turbine failures through combinations of excessive mechanical loads and fatigue-related loading.

Critical turbine components at risk are typically pitch and yaw bearings, drivetrain bearings and lubrication system, the electrical system and power-electronics. Furthermore down tower, tower-tower and tower-floater flange interfaces, floater-mooring-line pin or clamped linkages and interfaces, and all potentially impacting floater-turbine service life.

Mooring lines for semi-submersible, barge, and spar-type floater-turbine systems should therefore in our view be designed for optimal dynamic stiffness behaviour, or specifically a given amount of stretching as a function of frequency and load spectrum.

Polyester made easy

Our FibreMax’ dynamic stiffness optimized PolyMax – ‘Polyester made easy’ mooring lines offer up to 35% reduction in shock load levels compared to ‘traditional’ Polyester-based equivalents. A closely interlinked additional benefit is PolyMax’ linear behaviour, the (linear) relationship between wave-induced floater movement and thrust or tensional load in the mooring-line. PolyMax mooring lines therefore act functionally as a ‘natural’ shock absorber via the required compliance in the mooring system, which effectively eliminates the need for a separate mooring-line-incorporated shock absorber. However, this is exactly what at least one known FOW turbine supplier has done by combining his ‘traditional’ mooring lines with shock absorbers, and here in shallow-water conditions known as the most demanding operating condition.

Additional PolyMax benefits together offering substantial cumulative cost and risk reduction set against traditional Polyester rope application include ‘easy’ mooring line engineering, elimination of manual rope splicing, pre-stretching, bedding-in, and post-tensioning. Final benefits include FibreMax standard use of integrated end-terminations and, scalable capacity and local content opportunities!

Proven Performance with the FibreMax

Line Configurator

Proven Performance with the FibreMax Line Configurator

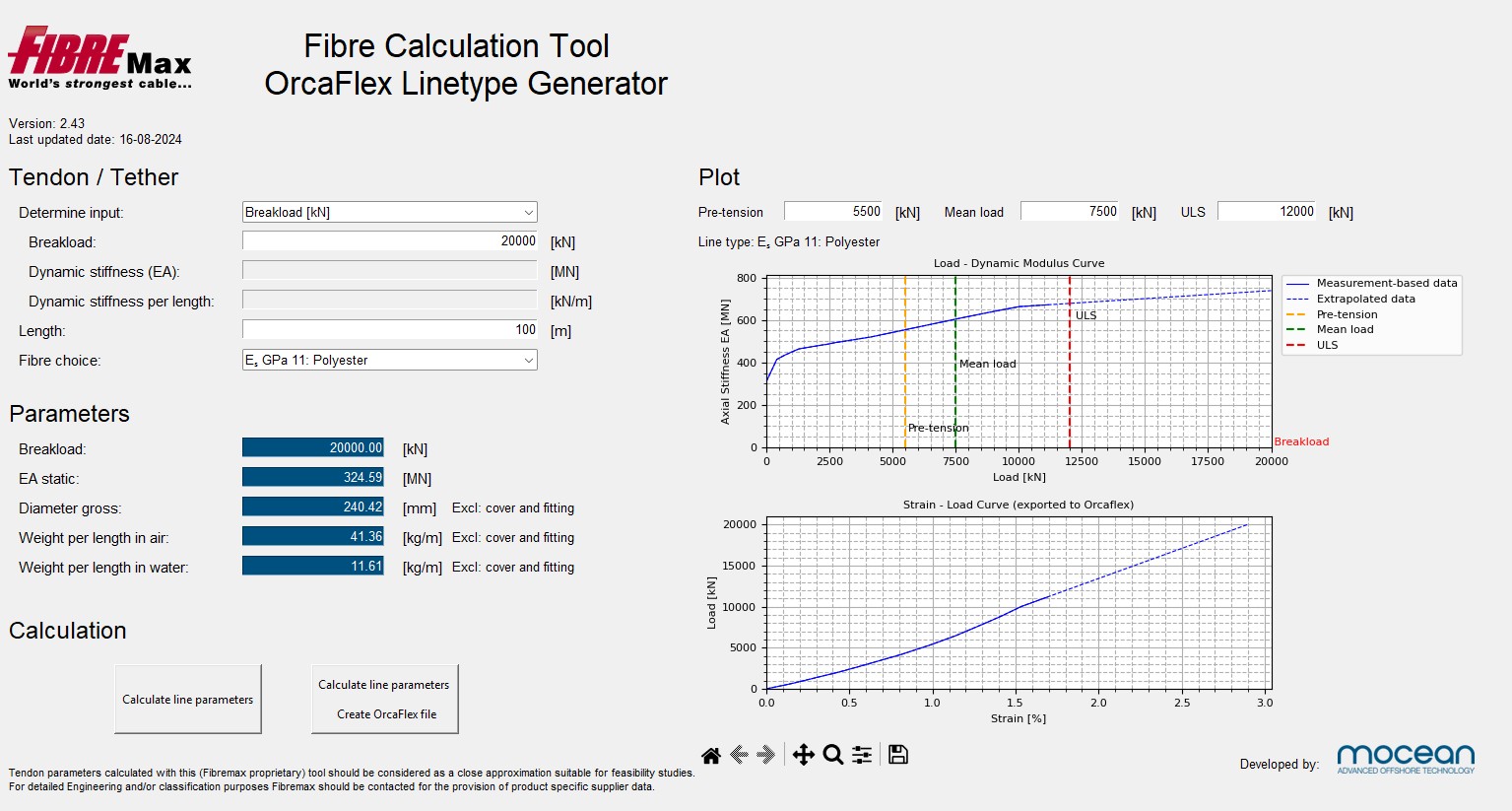

FibreMax takes the guesswork out of mooring system design with its proprietary Line Configurator—a powerful proprietary tool that enables demonstrable dynamic behavior modeling based on real, tested data.

With the Line Configurator, engineers and designers can:

- Visualize and fine-tune mooring line performance in real time

- Access exact dynamic stiffness curves tailored to their specific configuration

- Eliminate generic assumptions and oversimplified stiffness profiles

For seamless integration into project simulations, the configurator offers a one-click export to OrcaFlex DLL file —ensuring your OrcaFlex modeling environment reflects reality with precision.

No more assumptions. No more approximations. Just exact data for exact modeling.

Robotized production

The FibreMax products portfolio comprises pendants, tendons, structural stay cables, guy wires and mooring lines from any synthetic fibres to any exact length up to currently 250m (in one length, hence connectable) in our Joure (Friesland Province, the Netherlands) facility. The almost fully automated production processes takes place at a ‘fleet’ of production robots, ranging from the first initial in-house robot up to the latest, largest and most advanced and again custom-designed successor type. Each next production robotized unit builds at previous designs while incorporating and benefitting from the latest innovations and technological insights, with parallel focus at continuously changing market outlook and application demands.

Our high-precision automated software-controlled production method at fundamental fibre process level is designed to be fully repeatable, whereby any process deviations through fault-prone manual tasks like the traditional rope splicing are completely eliminated.

The specific nature of FibreMax manufacture, together with the high-degree of product and process automation enables us to employ relatively low-skilled operators instead of certified rope splicing technicians requiring two-year training completion.

Calibrated test equipment

FibreMax has the in-house know-how and capabilities via our own subsidiary FibreTech to conduct relevant dynamic tests as well as destructive tests using state-of-the-art calibrated equipment.

More than two decades accumulated FibreMax’ product and process innovation IP is protected by more than 160 international patents.

We have been awarded the following technical and product quality certifications:

- DNV A.O.M. (Approval of Manufacturer)

- DNV Statement of Feasibility (FOW)

- Class NK A.I.P. (Approval in Principle)

- ABS - pending

Localisation

The high level of production automation enables FibreMax to fully meet and facilitate ‘local content requirements’ and ‘local supply chain development.’ These demands can be met by establishing temporary or permanent production facilities and by training local operators. Alternatively, through for instance the establishment of floating production units that could be deployed across the globe.

Our ultimate aim is to always offer our clients only those products that are really ‘fit-for-purpose’, together with an optimal ‘price-performance’ in mind.

Fibremax at the forefront of

The energy transition

Join the movement toward smarter, fit-for-purpose mooring solutions for the floating wind industry. With PolyMax, FibreMax is pushing the boundaries of what polyester mooring can achieve—enhancing turbine performance, safety, and certainty.